Latest Automotive Resistor Specifications

I. Introduction

In the ever-evolving landscape of automotive technology, resistors play a crucial role in ensuring the functionality and reliability of various electronic systems. Automotive resistors are components that limit the flow of electric current, providing essential functions in circuits ranging from power management to signal processing. This blog post aims to provide an in-depth overview of the latest specifications for automotive resistors, highlighting their types, key specifications, material composition, performance characteristics, industry standards, recent innovations, and applications.

II. Types of Automotive Resistors

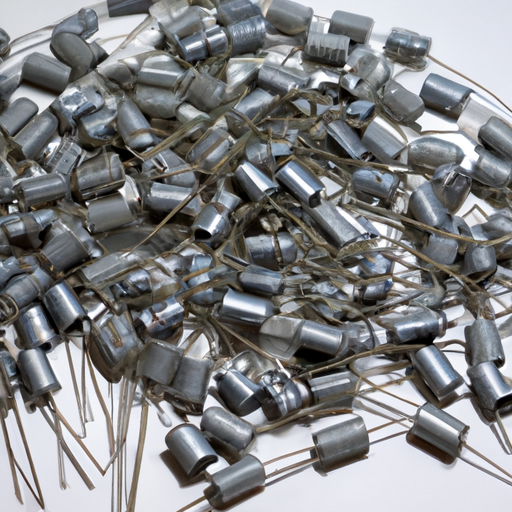

Automotive resistors can be broadly categorized into three main types: fixed resistors, variable resistors, and specialty resistors.

A. Fixed Resistors

1. **Carbon Composition Resistors**: These resistors are made from a mixture of carbon and a binding material. They are known for their high energy absorption capability and are often used in applications where high pulse loads are expected.

2. **Metal Film Resistors**: Offering better precision and stability than carbon composition resistors, metal film resistors are made by depositing a thin layer of metal onto a ceramic substrate. They are widely used in automotive applications due to their low noise and high reliability.

3. **Wirewound Resistors**: Constructed by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power levels and are often used in applications requiring high precision and stability.

B. Variable Resistors

1. **Potentiometers**: These resistors allow for adjustable resistance and are commonly used in applications such as volume controls and tuning circuits.

2. **Rheostats**: Similar to potentiometers, rheostats are used to control current flow in a circuit. They are typically used in applications requiring high power handling.

C. Specialty Resistors

1. **Thermistors**: These temperature-sensitive resistors are used in temperature sensing and control applications. They can be either NTC (negative temperature coefficient) or PTC (positive temperature coefficient), depending on their resistance behavior with temperature changes.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure. They are often used in automotive lighting systems.

III. Key Specifications of Automotive Resistors

Understanding the specifications of automotive resistors is essential for ensuring their proper function in automotive applications.

A. Resistance Value

1. **Ohm Range and Tolerance Levels**: Automotive resistors come in a wide range of resistance values, typically from a few ohms to several megaohms. Tolerance levels, which indicate how much the actual resistance can vary from the specified value, are crucial for precision applications.

2. **Importance of Precision in Automotive Applications**: In automotive systems, precise resistance values are critical for the accurate functioning of sensors, control units, and other electronic components.

B. Power Rating

1. **Definition and Significance**: The power rating of a resistor indicates the maximum amount of power it can dissipate without failing. This is measured in watts (W) and is crucial for ensuring that the resistor can handle the electrical load in automotive circuits.

2. **Common Power Ratings in Automotive Applications**: Automotive resistors typically have power ratings ranging from 0.1 W to several hundred watts, depending on their application.

C. Temperature Coefficient

1. **Explanation of Temperature Coefficient**: The temperature coefficient indicates how much a resistor's resistance changes with temperature. It is usually expressed in parts per million per degree Celsius (ppm/°C).

2. **Impact on Performance in Varying Conditions**: A low temperature coefficient is desirable in automotive applications, as it ensures stable performance across a wide range of operating temperatures.

D. Voltage Rating

1. **Importance of Voltage Ratings in Automotive Circuits**: The voltage rating indicates the maximum voltage that can be applied across a resistor without causing breakdown or failure. This is particularly important in automotive applications where voltage levels can fluctuate significantly.

2. **Common Voltage Ratings for Automotive Resistors**: Automotive resistors typically have voltage ratings ranging from 50 V to several kilovolts, depending on their intended use.

IV. Material Composition and Construction

The materials and construction techniques used in automotive resistors significantly impact their performance and reliability.

A. Common Materials Used in Automotive Resistors

1. **Carbon, Metal, and Ceramic**: Carbon is often used in carbon composition resistors, while metal films are used in metal film resistors. Ceramic materials are commonly used for their insulating properties and thermal stability.

B. Construction Techniques

1. **Surface Mount vs. Through-Hole Technology**: Surface mount technology (SMT) allows for smaller and lighter resistor designs, making them ideal for modern automotive applications. Through-hole technology, while bulkier, is still used in applications requiring higher power ratings.

2. **Encapsulation and Protection Methods**: Resistors are often encapsulated in protective materials to shield them from environmental factors such as moisture, dust, and chemicals, which are prevalent in automotive environments.

V. Performance Characteristics

The performance characteristics of automotive resistors are critical for their reliability and effectiveness in automotive applications.

A. Stability and Reliability

1. **Factors Affecting Stability in Automotive Environments**: Automotive resistors must withstand vibrations, temperature fluctuations, and exposure to chemicals. Their design and materials must ensure stability under these conditions.

2. **Testing Methods for Reliability**: Manufacturers often conduct rigorous testing, including thermal cycling, humidity testing, and vibration testing, to ensure that resistors meet automotive reliability standards.

B. Environmental Resistance

1. **Resistance to Temperature Fluctuations**: Automotive resistors must operate effectively across a wide temperature range, from extreme cold to high heat.

2. **Resistance to Moisture and Chemicals**: Resistors must be designed to resist moisture ingress and exposure to automotive fluids, such as oil and coolant.

C. Noise Characteristics

1. **Importance of Low Noise in Automotive Applications**: Low noise is essential in automotive circuits to prevent interference with sensitive electronic systems.

2. **Measurement and Specifications for Noise**: Noise characteristics are often specified in terms of voltage noise density, and manufacturers provide data to ensure that resistors meet the required noise performance.

VI. Industry Standards and Compliance

Adhering to industry standards is crucial for ensuring the safety and performance of automotive resistors.

A. Overview of Relevant Automotive Standards

1. **ISO, SAE, and Other Regulatory Bodies**: Various organizations, such as the International Organization for Standardization (ISO) and the Society of Automotive Engineers (SAE), set standards for automotive components, including resistors.

B. Importance of Compliance for Safety and Performance

Compliance with these standards ensures that automotive resistors meet safety, performance, and reliability requirements, which is critical for vehicle operation.

C. Certification Processes for Automotive Resistors

Manufacturers often undergo certification processes to demonstrate compliance with industry standards, which may include testing and documentation.

VII. Recent Innovations and Trends

The automotive industry is witnessing rapid advancements in resistor technology, driven by the need for more efficient and compact components.

A. Advances in Resistor Technology

1. **Miniaturization and Integration**: The trend towards smaller and more integrated components is leading to the development of miniaturized resistors that can fit into compact electronic systems.

2. **Smart Resistors and IoT Applications**: The rise of the Internet of Things (IoT) is driving the development of smart resistors that can communicate data and adapt to changing conditions in real-time.

B. Emerging Materials and Their Benefits

1. **Graphene and Other Advanced Materials**: Researchers are exploring the use of advanced materials like graphene, which offers superior conductivity and thermal properties, potentially revolutionizing resistor design.

C. Future Trends in Automotive Resistor Specifications

As automotive technology continues to evolve, we can expect to see further innovations in resistor specifications, including enhanced performance characteristics and new materials that improve reliability and efficiency.

VIII. Applications of Automotive Resistors

Automotive resistors are integral to various applications within vehicles, ensuring the proper functioning of electronic systems.

A. Role in Electronic Control Units (ECUs)

Resistors are essential in ECUs, where they help regulate voltage and current, ensuring that the control systems operate effectively.

B. Use in Sensors and Actuators

In sensors and actuators, resistors play a critical role in signal conditioning and processing, enabling accurate readings and responses.

C. Importance in Power Management Systems

Resistors are vital in power management systems, where they help manage energy distribution and ensure the efficient operation of electrical components.

IX. Conclusion

Understanding the specifications of automotive resistors is crucial for engineers, manufacturers, and automotive enthusiasts alike. As the automotive industry continues to innovate, the importance of reliable and efficient resistors will only grow. Future advancements in materials and technology will pave the way for even more sophisticated automotive systems, making it essential for stakeholders to stay informed about the latest developments in resistor specifications.

X. References

A comprehensive list of academic papers, industry reports, and standards will provide further reading and insights into the world of automotive resistors, ensuring that interested parties can delve deeper into this critical component of automotive technology.