What are the Product Standards for Capacitor Cabinets?

I. Introduction

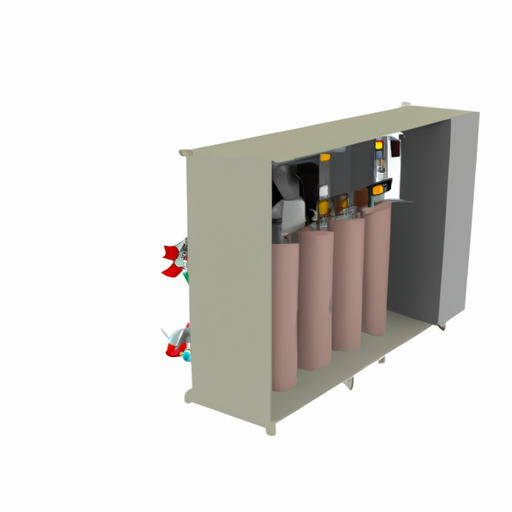

Capacitor cabinets are essential components in electrical systems, designed to house capacitor banks that improve power factor and voltage regulation. These cabinets play a crucial role in enhancing the efficiency and reliability of electrical networks, making them indispensable in various industrial and commercial applications. Given their importance, adhering to product standards is vital to ensure safety, performance, and reliability. This article aims to explore the product standards for capacitor cabinets, detailing the regulatory bodies involved, key standards, design considerations, testing protocols, and industry best practices.

II. Understanding Capacitor Cabinets

A. Function and Application of Capacitor Cabinets

Capacitor cabinets serve two primary functions: power factor correction and voltage regulation.

1. **Power Factor Correction**: Capacitor banks are used to counteract inductive loads in electrical systems, which can lead to a lagging power factor. By providing reactive power, capacitor cabinets help improve the power factor, reducing energy losses and lowering electricity costs.

2. **Voltage Regulation**: Capacitor cabinets also help maintain voltage levels within acceptable limits, especially in systems with fluctuating loads. By stabilizing voltage, they enhance the performance of electrical equipment and reduce the risk of damage.

B. Types of Capacitor Cabinets

Capacitor cabinets can be categorized based on their installation environment and functionality:

1. **Indoor vs. Outdoor Cabinets**: Indoor cabinets are designed for use in controlled environments, while outdoor cabinets are built to withstand harsh weather conditions. Outdoor cabinets often feature additional protective measures, such as weatherproof enclosures.

2. **Fixed vs. Automatic Capacitor Banks**: Fixed capacitor banks provide a constant level of reactive power, while automatic capacitor banks adjust their output based on real-time load conditions. This adaptability makes automatic systems more efficient in dynamic environments.

III. Regulatory Bodies and Standards

A. Overview of Key Regulatory Bodies

Several organizations establish and maintain standards for electrical equipment, including capacitor cabinets:

1. **International Electrotechnical Commission (IEC)**: The IEC develops international standards for electrical and electronic technologies, ensuring safety and efficiency across borders.

2. **Institute of Electrical and Electronics Engineers (IEEE)**: IEEE is a leading organization in electrical engineering, providing guidelines and standards that promote innovation and safety in electrical systems.

3. **National Electrical Manufacturers Association (NEMA)**: NEMA focuses on the electrical manufacturing industry in the United States, developing standards that ensure the quality and safety of electrical products.

B. Importance of Compliance with Standards

Compliance with established standards is crucial for several reasons:

1. **Safety**: Adhering to safety standards minimizes the risk of electrical hazards, protecting both personnel and equipment.

2. **Performance**: Standards ensure that capacitor cabinets operate efficiently and effectively, meeting the demands of various applications.

3. **Reliability**: Compliance with standards enhances the reliability of capacitor cabinets, reducing the likelihood of failures and downtime.

IV. Key Product Standards for Capacitor Cabinets

A. IEC Standards

1. **IEC 60871**: This standard specifies the requirements for shunt capacitors used in AC power systems, covering aspects such as design, testing, and performance.

2. **IEC 61921**: This standard addresses the performance and testing of capacitor banks, ensuring they meet the necessary operational criteria.

B. IEEE Standards

1. **IEEE C37.99**: This guide provides recommendations for the application of shunt capacitors, helping engineers design systems that effectively utilize these components.

2. **IEEE 18**: This standard outlines the procedures for sizing and testing shunt capacitors, ensuring they meet performance expectations.

C. NEMA Standards

1. **NEMA SG 1**: This standard covers the requirements for capacitor equipment, including design, construction, and performance criteria.

2. **NEMA 250**: This standard specifies the requirements for enclosures used in electrical equipment, ensuring they provide adequate protection against environmental factors.

V. Design and Construction Standards

A. Material Specifications

1. **Insulation Materials**: Capacitor cabinets must use high-quality insulation materials to prevent electrical leakage and ensure safety.

2. **Enclosure Materials**: The materials used for enclosures should be durable and resistant to environmental factors, such as moisture and corrosion.

B. Environmental Considerations

1. **Temperature Ratings**: Capacitor cabinets should be designed to operate within specified temperature ranges to prevent overheating and ensure longevity.

2. **Humidity and Corrosion Resistance**: Cabinets must be able to withstand varying humidity levels and resist corrosion, particularly in outdoor applications.

C. Safety Features

1. **Overvoltage Protection**: Capacitor cabinets should include mechanisms to protect against overvoltage conditions, which can damage equipment.

2. **Short-Circuit Protection**: Safety features must be in place to prevent damage in the event of a short circuit, ensuring the safety of both personnel and equipment.

VI. Testing and Quality Assurance

A. Importance of Testing in Product Standards

Testing is a critical component of ensuring that capacitor cabinets meet established standards. It verifies that the cabinets perform as intended and comply with safety regulations.

B. Common Testing Methods

1. **Dielectric Testing**: This test assesses the insulation properties of the capacitor cabinet, ensuring it can withstand high voltages without failure.

2. **Insulation Resistance Testing**: This method measures the resistance of the insulation material, helping to identify potential weaknesses.

3. **Thermal Imaging**: Thermal imaging can detect hot spots in electrical equipment, indicating potential issues that could lead to failure.

C. Certification Processes

1. **Third-Party Testing Organizations**: Independent organizations conduct testing and certification to verify compliance with standards, providing an additional layer of assurance.

2. **Compliance Documentation**: Manufacturers must maintain documentation demonstrating compliance with relevant standards, which is essential for regulatory inspections and audits.

VII. Industry Best Practices

A. Regular Maintenance and Inspection

Regular maintenance and inspection of capacitor cabinets are essential to ensure their continued performance and safety. This includes checking for signs of wear, corrosion, and other potential issues.

B. Upgrading to Meet New Standards

As technology and regulations evolve, manufacturers and users should be proactive in upgrading their capacitor cabinets to meet new standards, ensuring compliance and safety.

C. Training and Education for Personnel

Training personnel on the proper handling, maintenance, and operation of capacitor cabinets is crucial for safety and efficiency. Ongoing education helps keep staff informed about the latest standards and best practices.

VIII. Conclusion

In conclusion, product standards for capacitor cabinets are vital for ensuring safety, performance, and reliability in electrical systems. Compliance with standards set by organizations such as IEC, IEEE, and NEMA is essential for manufacturers and users alike. As technology advances, staying informed about new standards and best practices will be crucial for the continued effectiveness of capacitor cabinets. Manufacturers and users are encouraged to prioritize compliance and safety to enhance the performance of their electrical systems.

IX. References

- International Electrotechnical Commission (IEC) Standards

- Institute of Electrical and Electronics Engineers (IEEE) Standards

- National Electrical Manufacturers Association (NEMA) Standards

- Additional resources for further reading on capacitor cabinets and electrical standards.

This comprehensive overview of product standards for capacitor cabinets highlights the importance of adhering to established guidelines to ensure safety and efficiency in electrical systems. By understanding these standards, stakeholders can make informed decisions that enhance the reliability and performance of their electrical infrastructure.