Reactive Compensation Capacitor Components: An In-Depth Exploration

I. Introduction

In the realm of electrical engineering, the management of power quality is paramount. One of the critical components in achieving optimal power quality is the reactive compensation capacitor. These capacitors play a vital role in enhancing the efficiency and stability of electrical systems. This article aims to provide an in-depth exploration of reactive compensation capacitors, their components, applications, benefits, challenges, and future trends.

II. Understanding Reactive Power

A. Definition of Reactive Power

Reactive power is a concept that often confuses those new to electrical engineering. Unlike active power, which performs useful work (like lighting a bulb or powering a motor), reactive power does not contribute to the actual work done. Instead, it oscillates between the source and the load, primarily in inductive loads such as motors and transformers. Reactive power is measured in volt-amperes reactive (VAR).

B. Role of Reactive Power in Electrical Systems

Reactive power is essential for maintaining voltage levels in the system. It helps in the establishment of electric and magnetic fields necessary for the operation of inductive devices. Without adequate reactive power, voltage levels can drop, leading to inefficient operation and potential damage to equipment.

C. Consequences of Poor Reactive Power Management

Poor management of reactive power can lead to several issues, including increased energy costs, reduced system efficiency, and even equipment failure. Utilities may impose penalties on consumers with low power factors, making it crucial for businesses to manage their reactive power effectively.

III. Components of Reactive Compensation Capacitors

A. Capacitors

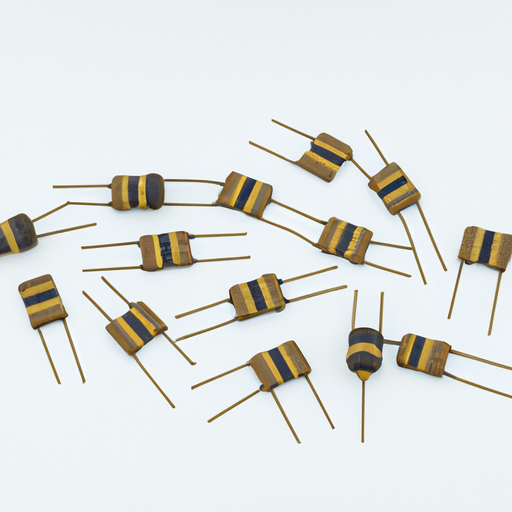

1. Types of Capacitors Used in Reactive Compensation

Reactive compensation capacitors come in various types, each serving specific functions:

Fixed Capacitors: These capacitors have a constant capacitance value and are typically used in applications where the reactive power requirement does not change.

Variable Capacitors: These allow for adjustments in capacitance, making them suitable for applications where reactive power needs fluctuate.

Power Factor Correction Capacitors: Specifically designed to improve the power factor of electrical systems, these capacitors are widely used in industrial and commercial settings.

2. Specifications and Ratings

When selecting capacitors for reactive compensation, several specifications must be considered:

Voltage Ratings: Capacitors must be rated for the maximum voltage they will encounter in the system to prevent breakdown.

Capacitance Values: The capacitance value determines how much reactive power the capacitor can provide.

Temperature Ratings: Capacitors must operate effectively within the temperature range of their environment to ensure reliability.

B. Inductors

1. Role of Inductors in Reactive Compensation

Inductors are often used in conjunction with capacitors to manage reactive power. They can help mitigate issues related to harmonics and resonance, which can arise in systems with significant reactive power.

2. Types of Inductors Used

Inductors used in reactive compensation can vary in design, including air-core and iron-core inductors, each suited for different applications and performance requirements.

C. Control Systems

1. Automatic Control Systems

Modern reactive compensation systems often incorporate automatic control systems that adjust capacitor banks based on real-time power factor measurements. This automation enhances efficiency and reduces the need for manual intervention.

2. Manual Control Systems

In some cases, manual control systems are still in use, allowing operators to adjust capacitor banks based on observed conditions. While less efficient than automatic systems, they can be effective in smaller installations.

3. Smart Grid Integration

With the advent of smart grid technology, reactive compensation systems can now integrate with broader energy management systems, allowing for more sophisticated control and optimization of reactive power.

IV. Applications of Reactive Compensation Capacitors

A. Industrial Applications

1. Manufacturing Facilities

In manufacturing, reactive compensation capacitors are crucial for maintaining power quality, especially in facilities with large motors and inductive loads. By improving the power factor, these capacitors help reduce energy costs and enhance equipment performance.

2. Motor Drives

Motor drives often require significant reactive power. Reactive compensation capacitors can help balance the power factor, leading to improved efficiency and reduced wear on equipment.

B. Commercial Applications

1. Office Buildings

In commercial settings, such as office buildings, reactive compensation capacitors can help manage the power factor, leading to lower energy bills and improved system reliability.

2. Retail Spaces

Retail spaces with various electrical equipment can benefit from reactive compensation to ensure that all devices operate efficiently without causing voltage drops.

C. Utility Applications

1. Transmission and Distribution Systems

Utilities use reactive compensation capacitors to manage voltage levels across transmission and distribution networks. This ensures that power is delivered efficiently and reliably to consumers.

2. Renewable Energy Integration

As renewable energy sources like wind and solar become more prevalent, reactive compensation capacitors play a vital role in integrating these sources into the grid, helping to manage the variability and maintain system stability.

V. Benefits of Reactive Compensation

A. Improved Power Factor

One of the primary benefits of reactive compensation is the improvement of the power factor, which leads to more efficient energy use and reduced costs.

B. Reduced Energy Costs

By improving the power factor, businesses can avoid penalties from utilities and reduce their overall energy costs, making reactive compensation a financially sound investment.

C. Enhanced System Stability

Reactive compensation helps maintain voltage levels, contributing to the overall stability of the electrical system and reducing the risk of outages.

D. Increased Equipment Lifespan

By reducing the strain on electrical equipment, reactive compensation can extend the lifespan of motors, transformers, and other devices, leading to lower maintenance and replacement costs.

VI. Challenges and Considerations

A. Sizing and Selection of Capacitors

Proper sizing and selection of capacitors are critical for effective reactive compensation. Oversized or undersized capacitors can lead to inefficiencies and potential system issues.

B. Harmonics and Resonance Issues

Reactive compensation systems can introduce harmonics into the electrical system, leading to resonance issues. Careful design and analysis are necessary to mitigate these effects.

C. Maintenance and Monitoring

Regular maintenance and monitoring of reactive compensation systems are essential to ensure their continued effectiveness and reliability.

D. Regulatory Compliance

Businesses must also consider regulatory compliance when implementing reactive compensation systems, as utilities may have specific requirements regarding power factor and reactive power management.

VII. Future Trends in Reactive Compensation

A. Advances in Capacitor Technology

Ongoing research and development in capacitor technology are leading to more efficient and reliable components, enhancing the performance of reactive compensation systems.

B. Integration with Renewable Energy Sources

As the energy landscape evolves, the integration of reactive compensation with renewable energy sources will become increasingly important for maintaining grid stability.

C. Smart Grid Developments

The rise of smart grid technology will enable more sophisticated control and optimization of reactive power, leading to improved efficiency and reliability.

D. Environmental Considerations

As sustainability becomes a priority, the environmental impact of reactive compensation systems will be a key consideration, driving the development of greener technologies.

VIII. Conclusion

In conclusion, reactive compensation capacitors are essential components in modern electrical systems, playing a crucial role in managing reactive power and improving overall system efficiency. By understanding their components, applications, and benefits, businesses and utilities can make informed decisions about implementing reactive compensation solutions. As technology continues to advance, the importance of these systems will only grow, making it imperative for stakeholders to stay informed and proactive in their approach to reactive power management.

IX. References

- Academic Journals on Electrical Engineering

- Industry Standards and Guidelines from IEEE and IEC

- Relevant Books and Articles on Power Quality and Reactive Compensation

This comprehensive exploration of reactive compensation capacitors highlights their significance in electrical systems and encourages further research and implementation in various applications.