Similar Recommendations for Resistor Factory Components

I. Introduction

Resistors are fundamental components in electronic circuits, playing a crucial role in controlling current flow, dividing voltages, and protecting sensitive components. Their importance cannot be overstated, as they are integral to the functionality of virtually all electronic devices, from simple circuits to complex systems. This article aims to provide recommendations for resistor factory components, catering to engineers, manufacturers, and hobbyists who seek to enhance their understanding and selection of resistors for various applications.

II. Understanding Resistor Components

A. Definition and Function of Resistors

A resistor is a passive electrical component that resists the flow of electric current, creating a voltage drop across its terminals. The primary function of a resistor is to limit current, divide voltages, and dissipate energy in the form of heat.

B. Types of Resistors

1. **Fixed Resistors**: These resistors have a constant resistance value and are the most commonly used type. They are available in various materials and power ratings, making them suitable for a wide range of applications.

2. **Variable Resistors (Potentiometers)**: These allow for adjustable resistance values, making them ideal for applications requiring fine-tuning, such as volume controls in audio equipment.

3. **Specialty Resistors**: This category includes thermistors, which change resistance with temperature, and photoresistors, which vary resistance based on light exposure. These resistors are essential in applications like temperature sensing and light detection.

C. Key Specifications to Consider

When selecting resistors, several key specifications must be considered:

1. **Resistance Value**: Measured in ohms, this indicates how much the resistor opposes current flow.

2. **Tolerance**: This specification indicates how much the actual resistance can vary from the stated value, typically expressed as a percentage.

3. **Power Rating**: Measured in watts, this indicates the maximum power the resistor can dissipate without being damaged.

4. **Temperature Coefficient**: This specification indicates how much the resistance changes with temperature, which is crucial for applications in varying environmental conditions.

III. Factors Influencing Resistor Selection

A. Application Requirements

1. **Circuit Design Considerations**: The specific requirements of the circuit, such as voltage levels and current flow, will dictate the type and specifications of the resistors needed.

2. **Environmental Conditions**: Factors such as temperature, humidity, and exposure to chemicals can affect resistor performance, making it essential to choose components that can withstand these conditions.

B. Material Considerations

1. **Carbon Composition**: These resistors are made from a mixture of carbon and ceramic and are known for their high energy absorption but have a higher tolerance range.

2. **Metal Film**: Offering better precision and stability, metal film resistors are ideal for applications requiring high accuracy.

3. **Wirewound**: These resistors are made by winding a metal wire around a core and are suitable for high-power applications due to their ability to handle significant heat.

C. Size and Form Factor

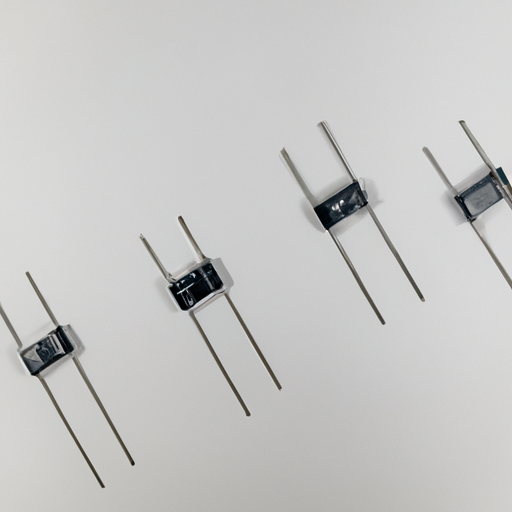

1. **Surface Mount vs. Through-Hole**: Surface mount resistors are smaller and suitable for automated assembly, while through-hole resistors are easier to handle and solder manually.

2. **Package Types**: The choice of package type can affect the resistor's performance, heat dissipation, and compatibility with circuit boards.

IV. Recommended Resistor Components for Factories

A. High-Precision Resistors

High-precision resistors are essential in applications where accuracy is paramount, such as in measurement and calibration equipment.

Recommended Brands and Models:

- Vishay's Z201 series offers excellent stability and low temperature coefficients.

- Yageo's RC series provides high precision with a tolerance of 0.1%.

B. High-Power Resistors

For applications that require handling significant power, high-power resistors are necessary to prevent overheating and failure.

Recommended Brands and Models:

- Ohmite's 50W series is designed for high power dissipation and is suitable for industrial applications.

- Caddock's MP series offers high power ratings with low thermal resistance.

C. Specialty Resistors

1. **Thermistors**: These are crucial for temperature sensing applications. NTC (Negative Temperature Coefficient) thermistors decrease resistance with increasing temperature, making them ideal for temperature measurement.

- **Recommended Brands**: EPCOS and Vishay offer reliable thermistors for various applications.

2. **Photoresistors**: Used in light detection applications, photoresistors change resistance based on light intensity.

- **Recommended Brands**: LDRs from brands like Hamamatsu are widely used in light-sensitive applications.

V. Sourcing Resistor Components

A. Factors to Consider When Choosing Suppliers

1. **Quality Assurance and Certifications**: Ensure that suppliers adhere to industry standards and provide quality assurance for their products.

2. **Lead Times and Availability**: Consider suppliers that can meet your production schedules and have a reliable inventory.

3. **Cost Considerations**: While cost is important, it should not compromise quality. Evaluate the total cost of ownership, including shipping and handling.

B. Recommended Suppliers and Distributors

1. **Major Electronic Component Distributors**: Companies like Digi-Key, Mouser Electronics, and Newark offer a wide range of resistors and other components.

2. **Niche Suppliers for Specialty Resistors**: For specific needs, suppliers like Thermometrics and Vishay specialize in thermistors and other specialty resistors.

VI. Best Practices for Resistor Usage in Factories

A. Proper Handling and Storage

Resistors should be handled with care to avoid damage. Store them in anti-static bags and in a controlled environment to prevent degradation.

B. Testing and Quality Control Measures

Implement regular testing and quality control measures to ensure that resistors meet specified tolerances and performance standards.

C. Integration into Manufacturing Processes

Incorporate resistors into manufacturing processes with attention to their specifications and application requirements to ensure optimal performance.

VII. Future Trends in Resistor Technology

A. Innovations in Resistor Materials and Designs

Advancements in materials science are leading to the development of resistors with improved performance characteristics, such as lower temperature coefficients and higher power ratings.

B. The Impact of Automation and Smart Manufacturing

Automation in manufacturing processes is streamlining the production of resistors, leading to increased efficiency and reduced costs.

C. Sustainability Considerations in Resistor Production

As the industry moves towards sustainability, manufacturers are exploring eco-friendly materials and processes to reduce the environmental impact of resistor production.

VIII. Conclusion

Selecting the right resistor components is crucial for the performance and reliability of electronic circuits. By understanding the various types of resistors, their specifications, and the factors influencing their selection, engineers and manufacturers can make informed decisions. The recommendations provided in this article aim to guide you in sourcing high-quality resistors that meet your specific needs. As technology continues to evolve, staying informed about the latest trends and innovations in resistor technology will be essential for maintaining a competitive edge in the industry.

IX. References

1. "Resistor Basics" - Electronics Tutorials

2. "Understanding Resistor Specifications" - Digi-Key Electronics

3. "The Role of Resistors in Circuit Design" - All About Circuits

4. "Quality Control in Electronic Manufacturing" - IEEE Xplore

5. "Future Trends in Electronic Components" - Electronic Design Magazine

This comprehensive guide serves as a valuable resource for anyone involved in the selection and application of resistors in electronic manufacturing, ensuring that you are well-equipped to make the best choices for your projects.