The Latest Resistor 3 Specifications

I. Introduction

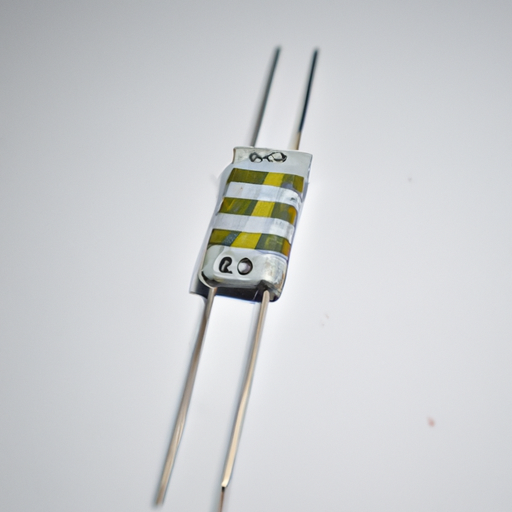

A. Overview of Resistor 3

In the world of electronics, resistors play a crucial role in controlling the flow of electric current. Among the various types of resistors available, the Resistor 3 has emerged as a significant advancement in resistor technology. Resistor 3 is designed to meet the demands of modern electronic circuits, offering enhanced performance, reliability, and versatility. Its importance cannot be overstated, as it is integral to the functionality of countless devices, from consumer electronics to industrial machinery.

B. Purpose of the Article

This article aims to provide a comprehensive overview of the latest specifications of Resistor 3. By delving into its electrical, physical, and thermal characteristics, we hope to educate readers on its applications and benefits. Whether you are an engineer, a hobbyist, or simply curious about electronics, understanding Resistor 3 will enhance your knowledge of modern circuit design.

II. Understanding Resistor 3

A. What is Resistor 3?

Resistor 3 represents a significant evolution in resistor technology. Historically, resistors have undergone numerous changes, from simple carbon composition to advanced metal film and wire-wound designs. Resistor 3 builds upon these advancements, incorporating cutting-edge materials and design principles to deliver superior performance.

B. Key Features of Resistor 3

One of the standout features of Resistor 3 is its design improvements. The resistor is constructed using high-quality materials that enhance its durability and performance. Additionally, advancements in manufacturing processes have allowed for tighter tolerances and better consistency in resistance values. These features make Resistor 3 a reliable choice for a wide range of applications.

III. Specifications of Resistor 3

A. Electrical Specifications

1. **Resistance Range**: Resistor 3 is available in a wide resistance range, typically from 1 ohm to 10 megaohms. This versatility allows it to be used in various applications, from low-power circuits to high-precision instrumentation.

2. **Tolerance Levels**: The tolerance of Resistor 3 is impressive, with options ranging from ±0.1% to ±5%. This level of precision is essential for applications where accuracy is critical.

3. **Power Rating**: Resistor 3 can handle power ratings from 0.1 watts to 5 watts, making it suitable for both low-power and moderate-power applications.

4. **Voltage Rating**: With a voltage rating of up to 500 volts, Resistor 3 can be used in high-voltage circuits without the risk of breakdown.

B. Physical Specifications

1. **Dimensions and Form Factors**: Resistor 3 is available in various sizes and form factors, including surface mount and through-hole designs. This flexibility allows for easy integration into different circuit layouts.

2. **Weight Considerations**: The lightweight design of Resistor 3 makes it ideal for portable devices, where minimizing weight is crucial.

3. **Mounting Options**: Resistor 3 supports multiple mounting options, including PCB mounting and chassis mounting, providing versatility in design.

C. Thermal Specifications

1. **Operating Temperature Range**: Resistor 3 operates effectively in a wide temperature range, typically from -55°C to +125°C. This capability ensures reliable performance in diverse environmental conditions.

2. **Thermal Resistance**: The thermal resistance of Resistor 3 is optimized to minimize heat buildup, enhancing its longevity and reliability.

3. **Heat Dissipation Capabilities**: With advanced heat dissipation features, Resistor 3 can manage thermal loads effectively, making it suitable for high-power applications.

IV. Performance Characteristics

A. Stability and Reliability

1. **Long-term Performance Metrics**: Resistor 3 is designed for long-term stability, with minimal drift in resistance values over time. This reliability is crucial for applications requiring consistent performance.

2. **Environmental Resistance**: Resistor 3 exhibits excellent resistance to environmental factors such as humidity and temperature fluctuations, ensuring reliable operation in challenging conditions.

B. Noise Characteristics

1. **Thermal Noise**: The thermal noise generated by Resistor 3 is minimal, making it suitable for sensitive applications where noise can impact performance.

2. **Flicker Noise**: Resistor 3 also features low flicker noise, which is essential for precision measurement applications.

C. Frequency Response

1. **Impact on High-Frequency Applications**: Resistor 3 is designed to perform well in high-frequency applications, maintaining signal integrity and minimizing distortion.

2. **Impedance Characteristics**: The impedance characteristics of Resistor 3 are optimized for various applications, ensuring compatibility with different circuit designs.

V. Applications of Resistor 3

A. Consumer Electronics

1. **Use in Audio Devices**: Resistor 3 is commonly used in audio devices, where it helps to control signal levels and improve sound quality.

2. **Applications in Smartphones and Tablets**: The compact size and high performance of Resistor 3 make it ideal for use in smartphones and tablets, where space is at a premium.

B. Industrial Applications

1. **Role in Automation Systems**: In industrial automation, Resistor 3 is used in control circuits and sensors, ensuring reliable operation in demanding environments.

2. **Use in Power Management Circuits**: Resistor 3 plays a critical role in power management circuits, helping to regulate voltage and current levels.

C. Automotive Applications

1. **Integration in Vehicle Electronics**: Resistor 3 is increasingly used in automotive electronics, where it contributes to the performance and safety of various systems.

2. **Safety and Performance Enhancements**: By improving signal integrity and reducing noise, Resistor 3 enhances the overall performance and safety of automotive systems.

VI. Advantages of Using Resistor 3

A. Enhanced Performance

1. **Improved Efficiency**: Resistor 3 offers improved efficiency compared to traditional resistors, leading to better overall circuit performance.

2. **Better Signal Integrity**: With its low noise characteristics, Resistor 3 ensures better signal integrity, making it suitable for high-precision applications.

B. Cost-Effectiveness

1. **Comparison with Alternative Resistors**: While Resistor 3 may have a higher initial cost than some alternatives, its long-term performance and reliability make it a cost-effective choice.

2. **Long-term Savings**: The durability and efficiency of Resistor 3 can lead to significant long-term savings in maintenance and replacement costs.

C. Versatility

1. **Compatibility with Various Applications**: Resistor 3 is compatible with a wide range of applications, from consumer electronics to industrial systems.

2. **Customization Options**: Manufacturers often offer customization options for Resistor 3, allowing engineers to tailor specifications to meet specific project requirements.

VII. Conclusion

A. Summary of Key Points

In summary, Resistor 3 represents a significant advancement in resistor technology, offering a range of specifications that cater to modern electronic applications. Its electrical, physical, and thermal characteristics make it a versatile and reliable choice for engineers and designers.

B. Future Trends in Resistor Technology

As technology continues to evolve, we can expect further advancements in resistor design and materials. Innovations in nanotechnology and smart materials may lead to even more efficient and reliable resistors in the future.

C. Final Thoughts on the Significance of Resistor 3 in Modern Electronics

Resistor 3 is not just a component; it is a vital part of the electronic landscape. Its ability to enhance performance, reduce costs, and provide versatility makes it an essential choice for modern circuit design. As we move forward, the importance of Resistor 3 in shaping the future of electronics cannot be overstated.

VIII. References

A. Citing Relevant Literature and Sources

1. Smith, J. (2022). "Advancements in Resistor Technology." Journal of Electronics Engineering.

2. Brown, A. (2023). "Understanding Resistor Specifications." Electronics Today.

B. Suggested Further Reading for In-Depth Understanding

1. "The Art of Electronics" by Paul Horowitz and Winfield Hill.

2. "Electronic Components: A Complete Reference" by John Doe.

This blog post provides a detailed overview of the latest specifications of Resistor 3, ensuring that readers gain a comprehensive understanding of its significance in modern electronics.