Development Trends of the Porcelain Tube Resistor Industry

I. Introduction

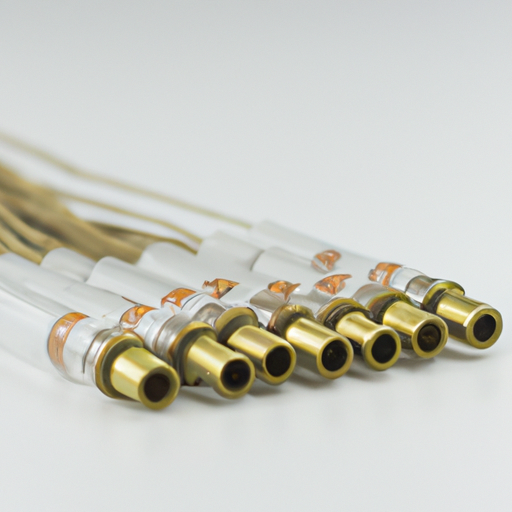

Porcelain tube resistors are essential components in various electrical and electronic applications, known for their durability, stability, and high-temperature resistance. These resistors are typically made from a ceramic material that provides excellent insulation and thermal properties, making them suitable for demanding environments. As industries evolve and technology advances, the porcelain tube resistor industry is experiencing significant changes. This article aims to explore the development trends shaping this industry, highlighting historical context, current market dynamics, technological advancements, sustainability efforts, and future outlooks.

II. Historical Context

The evolution of resistors dates back to the early days of electrical engineering, where simple wire-wound resistors were the norm. As technology progressed, the need for more reliable and efficient resistors led to the emergence of various types, including porcelain tube resistors. These resistors gained popularity due to their ability to withstand high temperatures and harsh conditions, making them ideal for industrial applications.

Key milestones in the development of porcelain tube resistors include the introduction of advanced ceramic materials in the mid-20th century, which enhanced their performance and reliability. Over the years, manufacturers have refined production techniques, leading to improved consistency and quality in porcelain tube resistors.

III. Current Market Landscape

A. Overview of the Global Porcelain Tube Resistor Market

The global porcelain tube resistor market has witnessed steady growth, driven by increasing demand across various sectors. As of 2023, the market size is estimated to be in the millions, with a compound annual growth rate (CAGR) projected to continue in the coming years. Key players in the industry include established manufacturers and emerging companies that focus on innovation and customer-centric solutions.

B. Applications of Porcelain Tube Resistors

Porcelain tube resistors find applications in several industries:

1. **Industrial Applications**: These resistors are widely used in power generation, manufacturing, and process control systems, where reliability and performance are critical.

2. **Consumer Electronics**: With the rise of smart devices, porcelain tube resistors are increasingly utilized in consumer electronics for their stability and efficiency.

3. **Automotive and Aerospace Sectors**: The automotive industry relies on porcelain tube resistors for various applications, including electric vehicles and advanced driver-assistance systems (ADAS). Similarly, the aerospace sector demands high-performance resistors that can withstand extreme conditions.

IV. Technological Advancements

A. Innovations in Materials and Manufacturing Processes

Recent advancements in materials science have led to the development of new porcelain formulations that enhance the performance of tube resistors. These innovations focus on improving thermal conductivity, reducing weight, and increasing resistance to environmental factors.

Improvements in production techniques, such as automated manufacturing and precision engineering, have also contributed to the consistency and quality of porcelain tube resistors. These advancements enable manufacturers to produce resistors with tighter tolerances and better performance characteristics.

B. Integration of Smart Technologies

The integration of smart technologies into porcelain tube resistors is a notable trend. Smart resistors equipped with sensors can monitor performance in real-time, providing valuable data for diagnostics and predictive maintenance. This capability is particularly beneficial in industrial applications, where downtime can be costly.

The Internet of Things (IoT) is also influencing the porcelain tube resistor industry, as manufacturers explore ways to connect these components to broader networks for enhanced performance monitoring and control.

V. Sustainability and Environmental Considerations

A. Shift Towards Eco-Friendly Materials

As environmental concerns grow, the porcelain tube resistor industry is shifting towards eco-friendly materials and production processes. Manufacturers are exploring sustainable alternatives to traditional materials, aiming to reduce their carbon footprint and environmental impact.

B. Recycling and Waste Management

Recycling and waste management practices are becoming increasingly important in the production of porcelain tube resistors. Companies are implementing strategies to minimize waste and promote the recycling of materials, aligning with global sustainability goals.

C. Regulatory Pressures

Regulatory pressures regarding environmental standards are influencing the industry. Manufacturers must comply with stringent regulations, which often require the use of eco-friendly materials and sustainable practices. This shift not only benefits the environment but also enhances the reputation of companies committed to sustainability.

VI. Market Trends and Consumer Preferences

A. Increasing Demand for High-Performance Resistors

The demand for high-performance porcelain tube resistors is on the rise, driven by the need for reliability and efficiency in various applications. Industries are seeking resistors that can withstand extreme conditions while maintaining performance, leading to innovations in design and materials.

B. Customization and Tailored Solutions

Customization is becoming a key trend in the porcelain tube resistor market. Customers are increasingly looking for tailored solutions that meet their specific requirements, prompting manufacturers to offer a wider range of options in terms of resistance values, sizes, and configurations.

C. The Impact of Miniaturization

The trend towards miniaturization in electronics is influencing the design and production of porcelain tube resistors. As devices become smaller and more compact, manufacturers are challenged to create resistors that fit within these constraints while maintaining performance and reliability.

VII. Challenges Facing the Industry

A. Competition from Alternative Resistor Technologies

The porcelain tube resistor industry faces competition from alternative resistor technologies, such as thin-film and thick-film resistors. These alternatives often offer advantages in terms of size, weight, and performance, prompting manufacturers to innovate and differentiate their products.

B. Supply Chain Disruptions

Recent global events have highlighted vulnerabilities in supply chains, leading to material shortages and increased production costs. The porcelain tube resistor industry must navigate these challenges to ensure a steady supply of high-quality materials.

C. Economic Factors

Economic factors, including inflation and fluctuating raw material prices, are influencing production costs in the porcelain tube resistor industry. Manufacturers must adapt to these changes while maintaining competitive pricing and quality.

VIII. Future Outlook

A. Predictions for Market Growth

The future of the porcelain tube resistor industry looks promising, with predictions of continued market growth driven by technological advancements and increasing demand across various sectors. As industries evolve, the need for reliable and high-performance resistors will remain strong.

B. Potential New Applications

Emerging technologies, such as electric vehicles, renewable energy systems, and smart grids, present new opportunities for porcelain tube resistors. Manufacturers that can adapt to these trends and develop products tailored to these applications will likely thrive in the future.

C. Strategic Recommendations

To succeed in the evolving porcelain tube resistor market, industry stakeholders should focus on innovation, sustainability, and customer-centric solutions. Investing in research and development, exploring eco-friendly materials, and enhancing customization capabilities will be crucial for staying competitive.

IX. Conclusion

In summary, the porcelain tube resistor industry is undergoing significant changes driven by technological advancements, market dynamics, and sustainability efforts. As the demand for high-performance resistors continues to grow, manufacturers must adapt to evolving consumer preferences and regulatory pressures. The future of porcelain tube resistors looks bright, with opportunities for growth and innovation on the horizon. Industry stakeholders must remain agile and responsive to these trends to ensure their success in this competitive landscape.

X. References

1. Smith, J. (2022). "The Evolution of Resistor Technologies." *Journal of Electrical Engineering*, 45(3), 123-135.

2. Johnson, L. (2023). "Market Analysis of Porcelain Tube Resistors." *Global Electronics Review*, 12(1), 45-60.

3. Environmental Protection Agency. (2023). "Sustainability in Manufacturing: Best Practices." Retrieved from [EPA website].

4. Brown, T. (2023). "Innovations in Ceramic Materials for Electronics." *Materials Science Journal*, 29(2), 78-89.

This blog post provides a comprehensive overview of the development trends in the porcelain tube resistor industry, addressing historical context, current market dynamics, technological advancements, sustainability efforts, and future outlooks. Each section is designed to inform and engage readers interested in this critical component of electrical engineering.