The Role of Capacitors and Product Training Precautions

I. Introduction

Capacitors are fundamental components in electronic circuits, playing a crucial role in the functionality and efficiency of various devices. Defined as passive electrical components that store and release electrical energy, capacitors are essential for a wide range of applications, from energy storage to signal processing. As technology continues to evolve, the importance of understanding capacitors and their applications becomes increasingly vital, particularly in the context of product training. This blog post will explore the role of capacitors in electronic circuits, the significance of product training, and the precautions necessary to ensure safe and effective handling of these components.

II. Understanding Capacitors

A. Basic Principles of Capacitors

At its core, a capacitor consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy. The primary function of a capacitor is to store and release electrical energy, making it an essential component in various electronic applications.

There are several types of capacitors, each with unique characteristics suited for specific applications. Common types include:

Ceramic Capacitors: Known for their stability and reliability, ceramic capacitors are widely used in high-frequency applications.

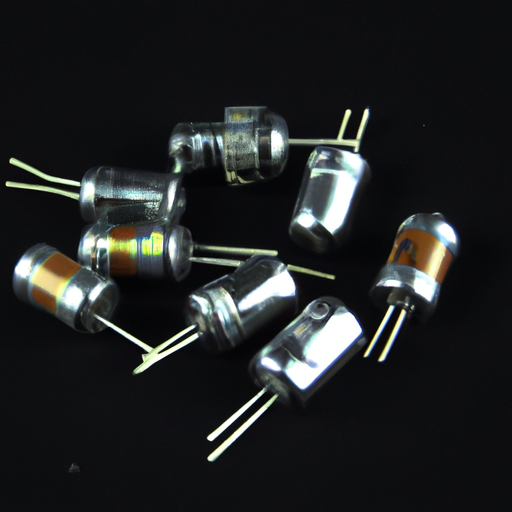

Electrolytic Capacitors: These capacitors offer high capacitance values and are often used in power supply circuits.

Tantalum Capacitors: Known for their compact size and high capacitance, tantalum capacitors are commonly used in portable electronics.

B. Key Parameters of Capacitors

Understanding the key parameters of capacitors is essential for selecting the right component for a specific application. Some of the most important parameters include:

1. **Capacitance**: Measured in farads (F), capacitance indicates the amount of electrical charge a capacitor can store.

2. **Voltage Rating**: This parameter specifies the maximum voltage a capacitor can handle without failing.

3. **Equivalent Series Resistance (ESR)**: ESR is a measure of the internal resistance of a capacitor, affecting its efficiency and performance.

4. **Temperature Coefficient**: This parameter indicates how a capacitor's capacitance changes with temperature, which is crucial for applications in varying environmental conditions.

C. Applications of Capacitors in Various Industries

Capacitors find applications across multiple industries, including:

Consumer Electronics: In devices like smartphones and televisions, capacitors are used for energy storage, filtering, and signal processing.

Automotive: Capacitors play a vital role in automotive electronics, including power management systems and audio equipment.

Industrial Machinery: In industrial settings, capacitors are used for motor starting, power factor correction, and energy storage.

Renewable Energy Systems: Capacitors are essential in solar inverters and wind turbine systems, helping to manage energy flow and improve efficiency.

III. The Role of Capacitors in Electronic Circuits

Capacitors serve several critical functions in electronic circuits, including:

A. Energy Storage and Release

Capacitors can store energy and release it when needed, making them ideal for applications requiring temporary energy storage, such as in power supply circuits.

B. Filtering and Smoothing

In power supply circuits, capacitors are used to filter out voltage fluctuations and smooth the output, ensuring a stable power supply for electronic devices.

C. Timing Applications

Capacitors are integral to timing circuits, where they work in conjunction with resistors to create time delays in electronic systems.

D. Coupling and Decoupling

Capacitors are used to couple signals between different stages of a circuit while blocking DC voltage, allowing only AC signals to pass through. They also decouple power supply lines, reducing noise and improving performance.

E. Signal Processing

In signal processing applications, capacitors help shape and modify signals, enabling various functionalities in audio and communication systems.

IV. Importance of Product Training

A. Overview of Product Training in the Electronics Industry

Product training is essential in the electronics industry, particularly for components like capacitors. It ensures that engineers, technicians, and end-users understand the specifications, applications, and safe handling of these components.

B. Objectives of Product Training

The primary objectives of product training include:

1. **Understanding Product Specifications**: Trainees learn about the different types of capacitors, their parameters, and how to select the appropriate component for specific applications.

2. **Safe Handling and Installation**: Training emphasizes the importance of safety when working with capacitors, including proper handling techniques and installation practices.

3. **Troubleshooting and Maintenance**: Product training equips participants with the skills to identify and resolve issues related to capacitors, ensuring optimal performance and longevity.

C. Target Audience for Product Training

Product training is beneficial for various stakeholders, including:

Engineers and Technicians: Those involved in the design, testing, and maintenance of electronic systems.

Sales and Marketing Teams: Professionals who need to understand product specifications to effectively communicate with customers.

End-Users: Individuals who use electronic devices and need to understand the role of capacitors in their functionality.

V. Precautions in Product Training Related to Capacitors

A. Safety Considerations

Safety is paramount when working with capacitors, particularly due to the potential risks associated with high voltage levels. Key safety considerations include:

1. **Understanding Voltage Levels and Risks**: Trainees must be aware of the voltage ratings of capacitors and the associated risks of electric shock or component failure.

2. **Proper Use of Personal Protective Equipment (PPE)**: Wearing appropriate PPE, such as gloves and safety goggles, is essential to minimize risks during handling and installation.

B. Handling and Storage of Capacitors

Proper handling and storage of capacitors are crucial to prevent damage and ensure reliability. Key practices include:

1. **Avoiding Damage to Components**: Trainees should be trained to handle capacitors carefully, avoiding physical stress that could lead to failure.

2. **Proper Storage Conditions**: Capacitors should be stored in a controlled environment, away from extreme temperatures and humidity, to maintain their performance.

C. Installation Best Practices

Correct installation practices are vital for the performance and longevity of capacitors. Important considerations include:

1. **Correct Orientation and Placement**: Some capacitors, such as electrolytic capacitors, have polarity and must be installed in the correct orientation.

2. **Soldering Techniques**: Proper soldering techniques are essential to avoid damaging capacitors during installation.

D. Testing and Troubleshooting

Training should also cover testing and troubleshooting techniques, including:

1. **Using Appropriate Tools and Methods**: Trainees should learn to use multimeters and other testing equipment to assess capacitor performance.

2. **Recognizing Signs of Failure**: Understanding the common signs of capacitor failure, such as bulging or leaking, is crucial for timely intervention.

VI. Case Studies and Real-World Applications

A. Examples of Capacitor Failures and Their Consequences

Real-world examples of capacitor failures highlight the importance of proper training and handling. For instance, a failure in a power supply capacitor can lead to device malfunction, resulting in costly repairs and downtime.

B. Successful Product Training Programs and Their Impact

Companies that invest in comprehensive product training programs often see improved performance and reduced failure rates. For example, a manufacturer of consumer electronics reported a significant decrease in warranty claims after implementing a robust training program for their technicians.

C. Lessons Learned from Industry Practices

The electronics industry has learned valuable lessons from past failures, emphasizing the need for thorough training and adherence to best practices in handling capacitors.

VII. Conclusion

In conclusion, capacitors play a vital role in electronic circuits, serving various functions that enhance the performance and reliability of devices. As technology continues to advance, the importance of thorough product training cannot be overstated. By understanding the specifications, safe handling practices, and troubleshooting techniques related to capacitors, professionals can ensure optimal performance and safety in their applications. Ultimately, a commitment to best practices in handling capacitors will lead to improved outcomes in the electronics industry.

VIII. References

- Academic journals and articles on capacitor technology and applications.

- Industry standards and guidelines for capacitor handling and safety.

- Manufacturer specifications and training materials for various types of capacitors.

This blog post provides a comprehensive overview of the role of capacitors in electronic circuits and the importance of product training, emphasizing the precautions necessary for safe and effective handling. By understanding these concepts, professionals can enhance their expertise and contribute to the success of their projects in the electronics industry.