Understanding Chip Inductors: A Comprehensive Guide

I. Introduction

In the world of electronics, components play a crucial role in the functionality and efficiency of devices. Among these components, chip inductors stand out as essential elements in various applications. This article aims to provide a comprehensive understanding of chip inductors, their significance in modern electronics, and the factors to consider when selecting the right one for your needs.

II. What is an Inductor?

A. Basic Principles of Inductance

1. Definition of Inductance

Inductance is a property of an electrical conductor that opposes changes in current. When current flows through a coil of wire, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage in the coil that opposes the change in current. This phenomenon is known as electromagnetic induction.

2. How Inductors Work

Inductors store energy in the magnetic field created by the current flowing through them. When the current is steady, the inductor acts like a short circuit, allowing current to flow freely. However, when the current changes, the inductor resists this change, which can be useful in filtering, energy storage, and signal processing applications.

B. Types of Inductors

Inductors come in various forms, each suited for specific applications:

1. Air Core Inductors

These inductors use air as the core material and are typically used in high-frequency applications due to their low losses.

2. Iron Core Inductors

Iron core inductors have a core made of iron, which increases inductance but can introduce losses at high frequencies.

3. Ferrite Core Inductors

Ferrite core inductors use ferrite materials, which provide high inductance with low losses, making them suitable for a wide range of applications.

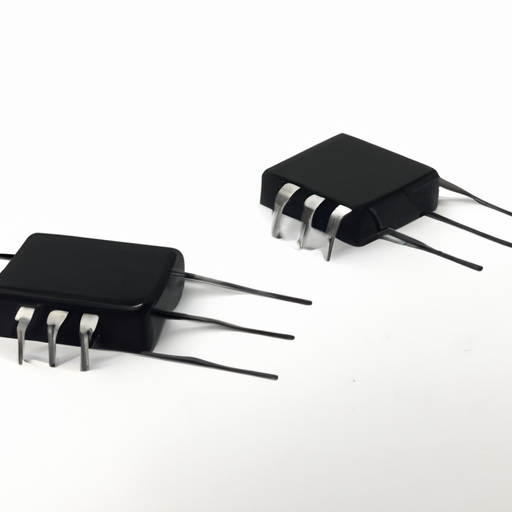

4. Chip Inductors

Chip inductors are a type of inductor that is miniaturized and designed for surface mounting on printed circuit boards (PCBs). They are widely used in modern electronics due to their compact size and efficiency.

III. Overview of Chip Inductors

A. Definition and Characteristics

1. Size and Form Factor

Chip inductors are small, typically measuring just a few millimeters in size. Their compact form factor allows for high-density circuit designs, making them ideal for applications where space is limited.

2. Material Composition

Chip inductors are usually made from a combination of ceramic and metal materials. The core is often made from ferrite, which provides high magnetic permeability, while the winding is typically made from copper or aluminum.

B. Comparison with Other Inductor Types

1. Advantages of Chip Inductors

Space Efficiency: Their small size allows for more components to be placed on a PCB, which is crucial for modern electronics.

Low Profile: Chip inductors have a low profile, making them suitable for slim devices.

High Performance: They offer good inductance values and low DC resistance, contributing to overall circuit efficiency.

2. Limitations of Chip Inductors

Power Handling: Chip inductors may have lower power handling capabilities compared to larger inductors.

Thermal Management: Due to their small size, managing heat dissipation can be challenging in high-power applications.

IV. Construction of Chip Inductors

A. Materials Used

1. Core Materials

The core of a chip inductor is typically made from ferrite, which enhances inductance and reduces losses. Ferrite materials are chosen for their magnetic properties and ability to operate at high frequencies.

2. Wire Materials

The wire used for winding the inductor is usually made from copper due to its excellent conductivity. In some cases, aluminum may also be used for cost-effective solutions.

B. Manufacturing Process

1. Coil Winding

The manufacturing process begins with winding the wire around the ferrite core. This process is critical as the number of turns and the winding technique directly affect the inductance value.

2. Encapsulation

Once the coil is wound, it is encapsulated in a protective material to shield it from environmental factors and mechanical stress. This encapsulation also helps in maintaining the inductor's performance over time.

3. Quality Control Measures

Quality control is essential in the manufacturing of chip inductors. Various tests are conducted to ensure that the inductors meet specified performance criteria, including inductance value, DC resistance, and self-resonant frequency.

V. Applications of Chip Inductors

A. Consumer Electronics

1. Smartphones

Chip inductors are widely used in smartphones for power management, signal filtering, and RF applications. Their compact size allows for efficient use of space within the device.

2. Laptops

In laptops, chip inductors are used in power supply circuits and for managing electromagnetic interference (EMI), ensuring stable performance.

B. Automotive Industry

1. Electric Vehicles

Chip inductors play a vital role in electric vehicles, particularly in power conversion and battery management systems, where efficiency is paramount.

2. Advanced Driver-Assistance Systems (ADAS)

In ADAS, chip inductors are used in sensors and communication systems, contributing to the overall safety and functionality of modern vehicles.

C. Telecommunications

1. Base Stations

Chip inductors are essential in base stations for signal processing and filtering, ensuring reliable communication in mobile networks.

2. Networking Equipment

In networking equipment, chip inductors help manage power and signal integrity, which is crucial for high-speed data transmission.

D. Industrial Applications

1. Automation Systems

Chip inductors are used in automation systems for control circuits, where reliability and compactness are critical.

2. Power Supplies

In power supply units, chip inductors help in filtering and energy storage, contributing to efficient power management.

VI. Key Specifications and Parameters

When selecting a chip inductor, several key specifications and parameters should be considered:

A. Inductance Value

The inductance value, measured in henries (H), indicates the inductor's ability to store energy in its magnetic field. It is crucial to choose an inductor with the appropriate inductance for your application.

B. Current Rating

The current rating specifies the maximum current the inductor can handle without overheating. Exceeding this rating can lead to failure or reduced performance.

C. DC Resistance (DCR)

DC resistance is the resistance of the inductor when a direct current flows through it. Lower DCR values are preferred as they result in less power loss.

D. Self-Resonant Frequency (SRF)

The self-resonant frequency is the frequency at which the inductor's reactance equals its resistance, causing it to behave like a resistor. It is essential to ensure that the operating frequency of your application is below the SRF.

E. Quality Factor (Q)

The quality factor indicates the efficiency of the inductor. A higher Q value means lower energy losses, making it more suitable for high-frequency applications.

VII. Selecting the Right Chip Inductor

A. Factors to Consider

1. Application Requirements

Understanding the specific requirements of your application is crucial. Consider factors such as inductance value, current rating, and operating frequency.

2. Environmental Conditions

Consider the environmental conditions in which the inductor will operate, including temperature, humidity, and potential exposure to contaminants.

B. Common Mistakes to Avoid

Ignoring Specifications: Always refer to the manufacturer's datasheet to ensure the inductor meets your application's requirements.

Overlooking Thermal Management: Ensure that the inductor can handle the thermal load of your application to prevent failure.

C. Resources for Further Research

For further research, consider consulting academic journals, industry publications, and manufacturer specifications. Online forums and communities can also provide valuable insights and experiences from other engineers and designers.

VIII. Future Trends in Chip Inductor Technology

A. Innovations in Materials and Design

As technology advances, new materials and designs are being developed to enhance the performance of chip inductors. Innovations such as nanomaterials and advanced manufacturing techniques are expected to improve efficiency and reduce size.

B. Impact of Miniaturization

The trend towards miniaturization in electronics will continue to drive the development of smaller and more efficient chip inductors, enabling even more compact designs in consumer electronics and other applications.

C. Role in Emerging Technologies (e.g., IoT, 5G)

Chip inductors will play a critical role in emerging technologies such as the Internet of Things (IoT) and 5G networks, where high performance and efficiency are essential for handling increased data rates and connectivity.

IX. Conclusion

In conclusion, chip inductors are vital components in modern electronics, offering compact size, high performance, and versatility across various applications. Understanding their construction, specifications, and applications is essential for engineers and designers looking to optimize their designs. As technology continues to evolve, staying informed about the latest trends and innovations in chip inductor technology will be crucial for future developments in the field.

X. References

- Academic Journals on Electrical Engineering and Electronics

- Industry Publications such as IEEE Spectrum and Electronics Weekly

- Manufacturer Specifications and Datasheets from leading inductor manufacturers

By exploring the world of chip inductors, you can enhance your understanding of their significance in electronics and make informed decisions in your design processes.